Unlocking Earth’s Riches, Globally

The mining sector is characterized by its diverse range of commodities, each with unique extraction methods and market demands. At UMA International Tradelink, we specialize in connecting miners, processors, and end-users, fostering mutually beneficial relationships that drive growth and sustainability.

Whether it’s supporting sustainable mining practices or navigating regulatory challenges, we are committed to delivering value through transparent and ethical business practices. Join us in harnessing the potential of mines and minerals to meet the evolving demands of global industries.

Our Mines & Mineral products

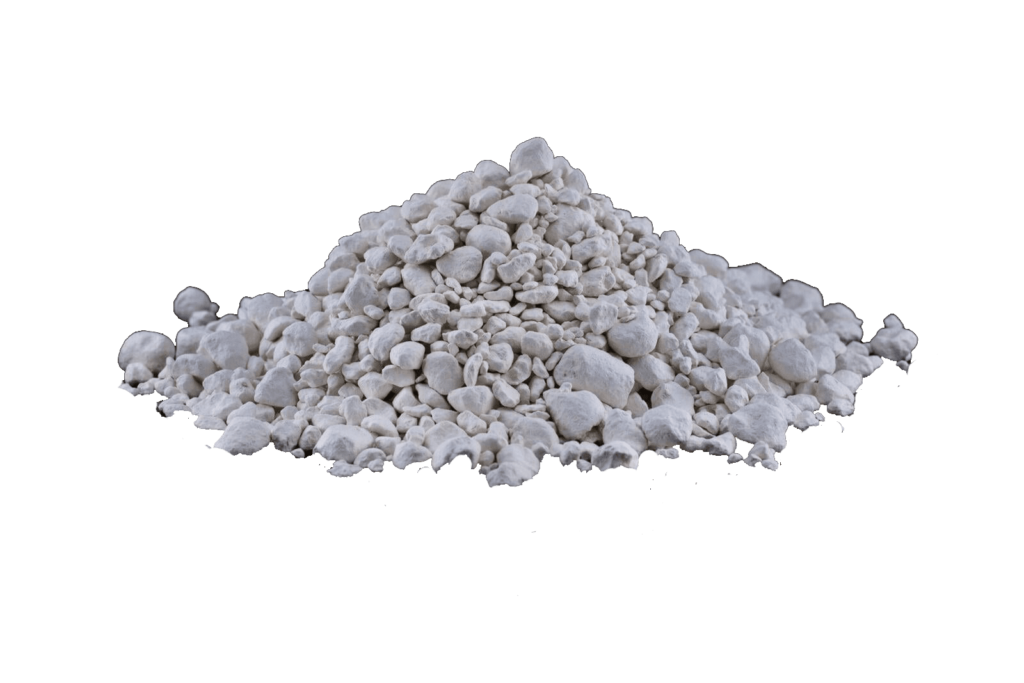

1. Kaolin

Kaolin, also called China clay, soft white clay that is an essential ingredient in the manufacture of porcelain and is widely used in the making of paper, rubber, paint, and many other products. It is distinguished from other industrial clays based on its fine particle size and pure colouring. Its ability to disperse in water makes it an ideal pigment.

1. White Kaolin: This is the most common type of kaolin, characterized by its white color and smooth texture. It is widely used in industries like ceramics, paper, and rubber.

2. Calcined Kaolin: This type is produced by heating kaolin to high temperatures, which improves its whiteness, hardness, and electrical properties. It is used in paints, plastics, and coatings.

3. Levigated Kaolin: This is a refined form of kaolin with a very fine particle size. It is used in cosmetics, pharmaceuticals, and food products.

4. Plastic Kaolin: This type has a high plasticity, making it suitable for use in ceramics and refractories.

5. Refractory Kaolin: This type has high heat resistance and is used in the production of firebricks and other refractory materials.

6. Paper Grade Kaolin: This type has specific properties that make it suitable for use in the paper industry, such as brightness, opacity, and viscosity.

7. Hydrous Kaolin Clay: This type is a naturally occurring clay mineral that contains water molecules. It’s known for its soft, smooth texture and high absorbency.

8. Calcined Kaolin Clay: This type is derived from hydrous kaolin clay by heating it to high temperatures. This process removes the water molecules, resulting in a denser, more porous material with improved heat resistance and oil absorption properties.

2.Bentonite

Bentonite: A versatile and absorbent clay mineral with a wide range of applications. Its unique properties, including high swelling capacity, cation exchange ability, and thixotropic behavior, make it an essential component in various industries.

High Swelling Capacity: Bentonite can absorb and retain significant amounts of water, expanding up to several times its original volume. This property makes it ideal for applications such as drilling fluids, where it helps stabilize the borehole and prevent wall collapse.

Cation Exchange Ability : Bentonite can exchange its cations (positively charged ions) with other cations in the surrounding environment. This property is utilized in water treatment, where bentonite can remove contaminants like heavy metals and pollutants.

Thixotropic Behavior: Bentonite exhibits thixotropy, meaning it becomes less viscous when agitated and more viscous when left undisturbed. This property is valuable in drilling fluids, where it helps maintain a stable viscosity under varying conditions

1. Swelling Bentonite (Sodium Bentonite)Key characteristic:

High swelling capacity when exposed to water.

Applications: Drilling muds, foundry sands, pet litter, cosmetics, and pharmaceuticals.

2. Non-Swelling Bentonite (Calcium Bentonite)

Key characteristic: Lower swelling capacity compared to sodium bentonite.

Applications: Construction materials, refractories, and animal feed.

3.Activated Bentonite

Key characteristic: Treated with chemicals to enhance its adsorbent properties.

Applications: Water purification, wastewater treatment, and pollution control.

3.Ball Clay

Ball clays is fine grained, highly plastic sedimentary clays, which fire to a light or near white color. They are used mainly in the manufacture of ceramic whiteware and are valued for their key properties of plasticity, fired strength and their light fired color.

Ball clays exhibit highly variable compositions and consist of a mixture, primarily of kaolinite, mica and quartz, with each contributing different properties to the clay. The crystallinity of the key component, kaolinite, has a marked influence on ceramic performance.

4. Silica sand

Silica sand, a natural, granular material composed primarily of quartz, is a cornerstone in countless industries. Its exceptional properties, including hardness, durability, and chemical inertness, make it an indispensable ingredient in a wide range of products. From construction materials to industrial applications, silica sand plays a vital role in shaping our modern world.

Key applications of silica sand include:

Construction: Used in concrete, mortar, and plaster for its strength and durability.

Glassmaking: The primary component in the production of glass, including windows, bottles, and speciality glass products.

Foundry: Used as a mould material in metal casting processes.

Water filtration: Its porous structure makes it an effective filter medium for removing impurities from water.

Industrial abrasives: Silica sand is used in sandblasting and other abrasive processes.

Our mines and mineral product range is not limited. We are expanding day by day and also catering to customers’ various mines and mineral requirements. please contact us for more details