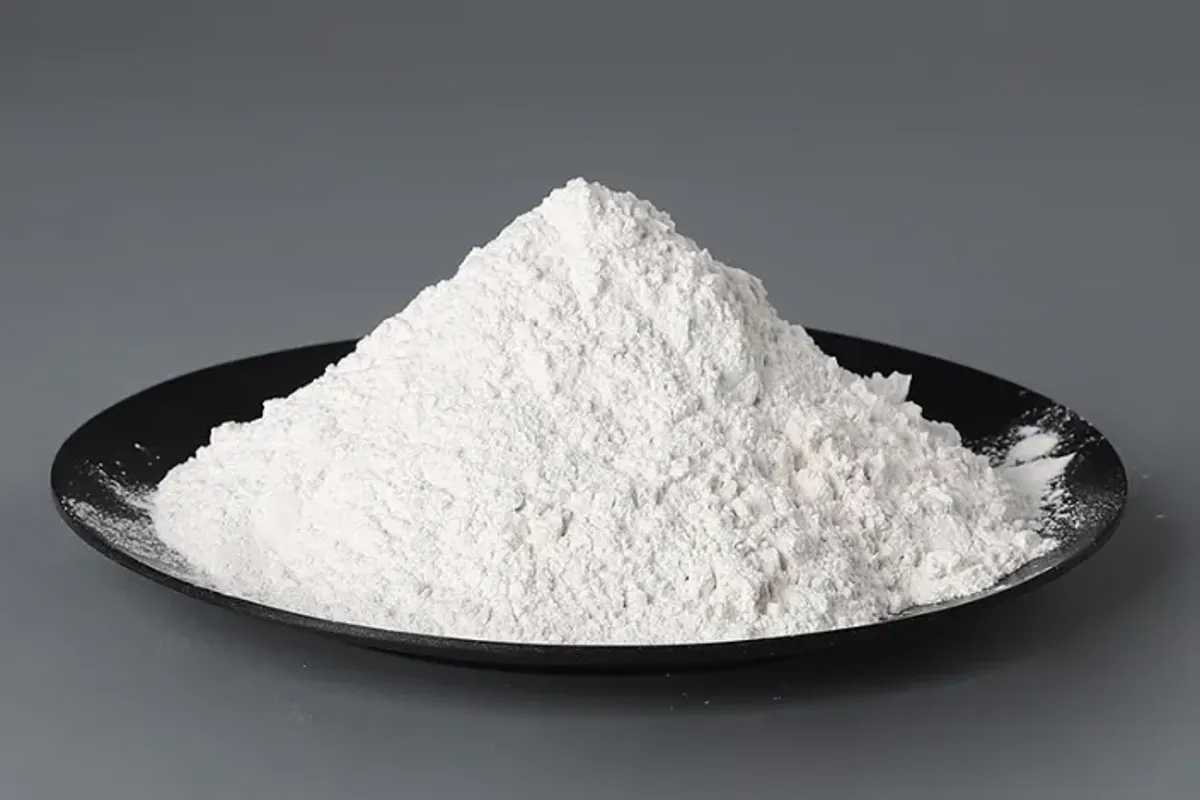

High-Purity Silica Sand for Industrial Excellence

When it comes to industrial raw materials, purity isn’t a luxury—it’s a necessity.”

Silica Sand, also known as industrial sand, is one of the most widely used materials in the world. Composed primarily of Silicon Dioxide (SiO₂), it is formed from naturally occurring quartz and is one of Earth’s most abundant minerals, formed over millions of years through geological processes.

At Uma International Tradelink, our Silica Sand is derived from rich, high-purity deposits in India, known for their exceptional brightness, low moisture, and consistent chemical stability. Its fine composition, inert properties, and high thermal resistance make it a critical material across industries—from glass manufacturing and foundry casting, to water filtration, construction, and ceramics.

Disclaimer

We do not deal in river or seashore sand, ensuring full compliance with environmental standards and sustainable mining practices. Note that Exporting it from India is restricted

- High SiO₂ Purity (up to 99.5%)

- Controlled Grain Size (Custom Mesh Options Available)

- Low Impurities (Fe₂O₃, Al₂O₃, Clay Content)

- Moisture-Controlled & Dry Processed

- Available in Bulk & Jumbo Bags

- Tested & Certified for International Standards

Technical Specifications of Silica Sand

| Elements | Percentage (%) |

|---|---|

| SiO2 | 98.50% Min |

| Fe2O3 | 0.05% Max |

| Al2O3 | 0.70% Max |

| CaO | 0.20% Max |

| TiO2 | 0.05% Max |

| MgO | 0.20% Max |

| Moisture | 0.50% Max (Dry Sand) |

Silica Sand Grade

| Parameters | UMA - Premium | UMA - Spiral | UMA - Regular |

|---|---|---|---|

| SiO2 | 99.1 % Min | 99 % Min | 98.5 % Min |

| Al2O3 | < 0.4 % | < 0.4 % | < 0.6 % |

| Fe2O3 | < 0.018 % | < 0.030 % | <0.060 %, <0.025 % |

| CaO | < 0.15 % | < 0.15 % | < 0.15 % |

| TiO2 | < 0.05 % | < 0.06 % | < 0.05 % |

| Moisture | NIL | 5% | 5% |

| Process | Dry | Wet and Dry | Wet and Dry |

| Grain Size | As Per Requirement | As Per Requirement | As Per Requirement |

Trusted Across Global Industries

Flat Glass, Float Glass &

Container Glass

Foundry Casting &

Metal Moulding

Construction &

Dry Mix Mortars

Paints, Plastics &

Ceramics

Filtration & Water

Treatment

Chemical and Refractory

Industries

Why Choose Our Silica Sand?

- Over a decade of experience in global mineral exports

- Customizable sizing, reliable supply, and consistent quality

- Sourced from high-grade deposits in Kutch, India

- ISO-compliant testing and quality assurance

- Transparent pricing, ethical trade practices

Additional Information

- Payment Mode : Cheque/Wire Transfer/L/C (Letter of Credit)

- Production Capacity: 20000 MT/month

- Delivery Time: Within 10 – 15 days

- Packaging: 25 kg To 1.4 MT Jumbo Bag

- Transport Mode: Sea Transport

- Jumbo Bags (1 MT / 1.4 MT)

- Custom labelling available

- CIF, FOB, and EXW options

- Global shipping with documentation support

Ready to place an order or need a custom quote?

Contact us at info@umainternationaltradelink.com or +91 9773146730.

We ship globally and are here to support your project every step of the way.

Clarity begins with purity—glass starts with exceptional silica.

Glass Grade Silica Sand is the cornerstone of high-quality glass manufacturing. It is primarily composed of very high-purity quartz (SiO₂ > 99%) and is meticulously processed to meet strict chemical and physical requirements. The defining characteristic is its low iron content, which prevents discoloration and ensures a clear, bright finish—essential for products like optical glass, containers, float glass, and solar panels.

UMA INTERNATIONAL TRADELINK sources its glass-grade silica sand from selective high-silica quarries. Through precision washing, drying, and sieving processes, we ensure uniform grain size, minimal impurities, and moisture-free product—ideal for melting without contamination.

Key Properties :

-

SiO₂ content typically Min 99%

SiO₂ content typically Min 99% -

Low Fe₂O₃ (< 0.03%)

Low Fe₂O₃ (< 0.03%) -

Uniform particle size distribution

Uniform particle size distribution -

Moisture-controlled & contaminant-free

Moisture-controlled & contaminant-free

For legal entities:

-

Float & Sheet Glass Manufacturing

Float & Sheet Glass Manufacturing -

Container Glass – Bottles, jars, and packaging

Container Glass – Bottles, jars, and packaging -

Solar Glass – For photovoltaic panels

Solar Glass – For photovoltaic panels -

Fiberglass & Insulation Products

Fiberglass & Insulation Products -

Optical & Decorative Glass

Optical & Decorative Glass

Consistency under heat—performance under pressure.

Engineered for precision in metal casting, UMA INTERNATIONAL TRADELINK’s Foundry Grade Silica Sand stands up to extreme heat and dimensional demands. Designed specifically for ferrous and non-ferrous foundries, our sand ensures structural integrity and superior casting finish under high-temperature conditions.

With a melting point around 1700°C and excellent thermal shock resistance, it provides the reliability required in modern casting systems. Our grains are sub-angular to round, striking the perfect balance between compactability and permeability—ideal for green sand molding, resin-coated cores, and no-bake systems.

Key Properties :

-

High thermal conductivity

High thermal conductivity -

Grain fineness controlled as per AFS standard

Grain fineness controlled as per AFS standard -

Low clay and organic content

Low clay and organic content -

Superior refractoriness and strength

Superior refractoriness and strength

For legal entities:

-

Ferrous and non-ferrous foundries

Ferrous and non-ferrous foundries -

Automotive castings (engine blocks, brake drums)

Automotive castings (engine blocks, brake drums) -

Heavy engineering castings

Heavy engineering castings -

Shell molding and core making

Shell molding and core making

Clean water starts with clean sand.

Water Filtration Grade Silica Sand acts as a natural, inert, and durable filter media that supports the mechanical filtration of water. It’s used extensively in municipal water treatment, industrial wastewater plants, and residential filtration systems to remove turbidity, suspended solids, and other contaminants.

Our filtration-grade silica sand is precisely graded and washed, offering uniform grain sizes that promote optimal flow rates and prevent clogging. With low acid solubility and high chemical resistance, it guarantees longevity and efficiency in multi-layer or pressure filter systems.

At UMA INTERNATIONAL TRADELINK, we supply sand in a variety of mesh sizes for single-layer and multi-media filters, ensuring compliance with IS 8419, AWWA B100, and NSF standards (where required).

Key Properties :

-

Clean, washed, and dried

Clean, washed, and dried -

Inert and chemically stable

Inert and chemically stable -

Precise grain size ranges: 0.45–0.55 mm, 0.71–1.25 mm, etc.

Precise grain size ranges: 0.45–0.55 mm, 0.71–1.25 mm, etc. -

Long filter life, no leaching of contaminants

Long filter life, no leaching of contaminants

For legal entities:

-

Municipal and industrial water purification

Municipal and industrial water purification -

Swimming pool filtration systems

Swimming pool filtration systems -

Effluent treatment plants (ETPs)

Effluent treatment plants (ETPs) -

Reverse osmosis (RO) pre-filtration

Reverse osmosis (RO) pre-filtration -

Agricultural and irrigation water systems

Agricultural and irrigation water systems

The foundation of durability is in every grain.

Construction Grade Silica Sand is used as a structural and functional component in the building and infrastructure sectors. It serves as a fundamental ingredient in concrete mixes, mortars, and road bases. Thanks to its angular grain structure, it provides excellent bonding and strength when mixed with cement and lime.

We supply coarse to fine-grained construction silica sand that conforms to IS 383 and ASTM C33 standards. Whether it’s for plastering, tiling, ready-mix concrete (RMC), or bedding under paving blocks—our sand ensures improved compressive strength and surface finish.

Key Properties :

-

Hard, durable quartz grains

Hard, durable quartz grains -

Angular to sub-angular grain shapes for optimal compactability

Angular to sub-angular grain shapes for optimal compactability -

Free from clay, silt, and organic matter

Free from clay, silt, and organic matter -

Compatible with cement and other binding agents

Compatible with cement and other binding agents

For legal entities:

-

Concrete and mortar production

Concrete and mortar production -

Ready-mix concrete (RMC) plants

Ready-mix concrete (RMC) plants -

Bricklaying and plastering

Bricklaying and plastering -

Road and pavement sub-base

Road and pavement sub-base -

Screed and floor leveling systems

Screed and floor leveling systems

High-purity silica—crafted by nature, engineered by industry.

Quartz Sand is a highly refined silica sand composed of ≥ 99.5% crystalline silica (SiO₂). Renowned for its exceptional hardness (7 on Mohs scale), chemical inertness, and thermal stability, it serves as a premium raw material in a wide range of advanced industrial applications.

At UMA INTERNATIONAL TRADELINK, our quartz sand undergoes rigorous processing to remove impurities, ensuring consistent particle size, color uniformity, and chemical purity. Whether used as a filler, abrasive, or component in synthetic surfaces, our quartz sand guarantees unmatched performance and reliability.

Key Properties :

-

Hard, durable quartz grains

Hard, durable quartz grains -

Angular to sub-angular grain shapes for optimal compactability

Angular to sub-angular grain shapes for optimal compactability -

Free from clay, silt, and organic matter

Free from clay, silt, and organic matter -

Compatible with cement and other binding agents

Compatible with cement and other binding agents

For legal entities:

-

Ceramic and vitrified tile industries

Ceramic and vitrified tile industries -

Paints and coatings

Paints and coatings -

Rubber and plastics as a functional filler

Rubber and plastics as a functional filler -

Semiconductor and solar industries

Semiconductor and solar industries

Fine. Pure. Powerful. A mineral that adds strength, shine, and stability.

Quartz Powder is a high-purity, finely ground form of crystalline silica (SiO₂), derived from carefully selected quartz lumps. It is white to off-white in color, extremely hard (Mohs hardness of 7), chemically inert, and highly durable. Its versatility, thermal resistance, and ability to provide gloss and reinforcement make it indispensable in numerous industries.

At UMA INTERNATIONAL TRADELINK, we offer premium-grade Quartz Powder that is micronized using advanced pulverizing technology. We provide customized mesh sizes — from 100 mesh to 500 mesh and even micronized forms — to suit specific applications across sectors like ceramics, paint, glass, construction, plastics, and electronics.

We ensure consistent quality, uniform particle size, and low impurities. Every batch is tested for whiteness, particle distribution, silica content, and moisture control.

Key Properties :

-

High Purity Silica (SiO₂ content: 99.2% – 99.7%)

High Purity Silica (SiO₂ content: 99.2% – 99.7%) -

Whiteness > 90%

Whiteness > 90% -

Hardness: 7 (Mohs scale)

Hardness: 7 (Mohs scale) -

Thermal stability up to 1000°C

Thermal stability up to 1000°C -

Inert to acids (except hydrofluoric acid)

Inert to acids (except hydrofluoric acid) -

Uniform particle size distribution – available in fine, super-fine, and micronized grades

Uniform particle size distribution – available in fine, super-fine, and micronized grades -

Low Iron (Fe₂O₃ < 0.04%) — ideal for white applications

Low Iron (Fe₂O₃ < 0.04%) — ideal for white applications

For legal entities:

Paints & Coatings

Quartz powder enhances durability, gloss, and chemical resistance in decorative and industrial coatings. It prevents cracking and improves hardness in powder coatings and wall putties.

Ceramics & Sanitaryware

Used in the body and glaze of tiles, porcelain, and sanitaryware for its strength, whiteness, and high melting point.

Glass Manufacturing

Acts as a raw material for container glass, float glass, and special glass due to its chemical purity and low iron.

Construction & RMC (Ready-Mix Concrete)

Improves strength, weather resistance, and water impermeability in dry mix mortars, grouts, and high-performance concrete.

Plastics, Rubber & PVC

Used as a functional filler in compounds to increase hardness, reduce shrinkage, and improve thermal stability and surface finish.

Foundry & Refractories

Enhances the performance of castables, molds, and refractory linings with excellent heat resistance and low reactivity.

Electronics & Solar

Ultra-pure quartz powder is used in semiconductors, silica crucibles, and solar-grade applications.